Trusted Silicone Product Manufacturer | Custom Silicone Molding & Processing Factory

At WH Silicone, we specialize in custom silicone product manufacturing, offering a full range of OEM silicone processing services including:

-

Liquid Silicone Rubber (LSR) Injection Molding

-

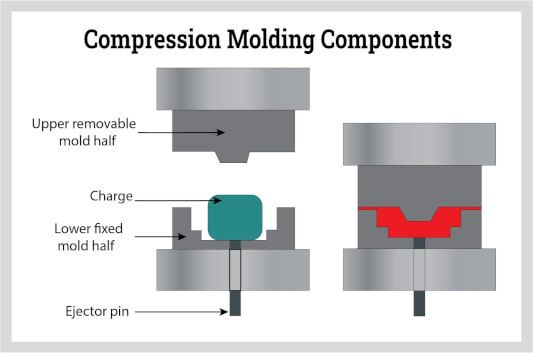

High-Temperature Vulcanized (HTV) Compression Molding

-

Room Temperature Vulcanized (RTV) Silicone Casting

-

Custom Silicone Extrusion

-

Silicone Overmolding & Post-Processing

We serve a wide range of industries—medical, baby care, kitchenware, automotive, consumer electronics, and industrial sealing—by providing tailored solutions for both prototype development and mass production.

Our Silicone Manufacturing Capabilities

LSR Injection Molding (Medical & Baby Care)

We provide FDA-grade LSR silicone molding services ideal for precision medical components, baby pacifiers, and wearables. Our cleanroom molding ensures hygiene and safety.

HTV Compression Molding (Industrial & Automotive)

For parts requiring durability and temperature resistance, our HTV silicone compression molding produces high-performance gaskets, vibration isolators, and engine seals.

RTV Silicone Casting (Electronics & Prototyping)

Our RTV silicone casting services are perfect for electronics encapsulation, mold prototypes, and flexible coatings.

Silicone Extrusion (Tubing & Profiles)

We offer custom silicone extrusion manufacturing for tubing, sealing strips, and continuous profiles used in medical, food, and appliance industries.

Secondary Operations & Surface Customization

Including overmolding, silicone-to-metal bonding, logo printing, laser engraving, and assembly.

Industries We Serve

We produce custom silicone components for high-value, regulated, and specialized markets:

Want to Develop Industry-Specific Silicone Parts?

Whether you're a medical device developer, kitchenware startup, or industrial supplier, WH Silicone delivers the materials, tooling, and manufacturing flexibility to bring your silicone ideas to life.

Why Choose WH Silicone?

Over 10 years of silicone processing experience

Advanced technologies in LSR, HTV, RTV, and extrusion

Custom mold design, engineering support, and rapid prototyping

Low MOQ for startups, scalable production for enterprise

Certified materials: FDA, LFGB, RoHS, ISO 10993