Custom Silicone Parts for Consumer Electronics & Wearables

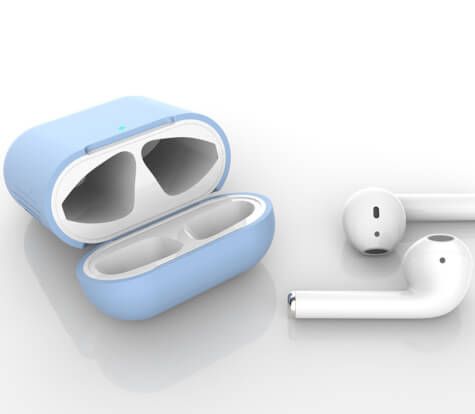

High-precision, skin-friendly silicone components tailored for modern technology – from smartwatches to earbuds.

At WH Silicone, we specialize in manufacturing high-quality silicone components for the consumer electronics and wearable device industries. Our products are engineered for durability, comfort, and performance—ideal for tech devices that are used daily and worn directly on the skin. Whether you need silicone bands, protective housings, or custom-molded seals, we deliver solutions that meet the most demanding OEM specifications.

Applications of Silicone in Consumer Electronics & Wearables

Versatile solutions for evolving tech products

Wearable Devices:

-

Smartwatch straps and wristbands

-

Fitness tracker silicone bands

-

Earbuds and ear tips

-

VR headset interface pads

-

Medical wearables enclosures and gaskets

-

Silicone rings and wearable tags

Consumer Electronics(H3):

-

Remote control silicone buttons

-

Smartphone and tablet protective cases

-

Charging cable strain relief components

-

Silicone sealing gaskets for smart devices

-

Silicone parts for audio, gaming, and smart home accessories

Our team supports diverse applications with custom formulations, ergonomic designs, and high-precision tooling. We work closely with global tech brands to develop innovative silicone solutions that enhance user experience and product performance.

Why Silicone for Consumer Electronics and Wearables?

Silicone is one of the most versatile and reliable materials for consumer electronics and wearable devices. It combines soft-touch comfort with outstanding durability, making it perfect for products used close to the body or exposed to daily handling.

-

✅ Skin-safe (FDA/LFGB compliant)

-

✅ Sweatproof and waterproof

-

✅ Flexible yet durable

-

✅ Excellent electrical insulation

-

✅ Resistant to UV, temperature, and aging

-

✅ Lightweight with high design adaptability

Custom Manufacturing Capabilities

Full-service OEM/ODM production from design to delivery

We provide end-to-end silicone component manufacturing services tailored for consumer electronics and wearables. Our factory is equipped for large-scale production with tight tolerances and fast turnaround times.

Our capabilities include:

Silicone molding: Liquid Silicone Rubber (LSR) Injection, Compression molding

Tolerances: ±0.05mm for precise fit in electronic housings

Surface Finishing: Matte, gloss, laser etching, pad printing

Assembly & Overmolding: Integration with plastic, metal, electronics

Material customization: Anti-yellowing, flame-retardant, biocompatible grades

Material Grades and Compliance

We use high-performance silicone materials specifically selected for use in electronics and direct skin contact.

-

FDA and LFGB-grade silicone for skin-wearable products

-

Medical-grade silicone for healthcare wearables

-

RoHS and REACH compliant materials

-

UL94 V-0 fire-retardant silicone for electronics

-

Anti-UV and anti-aging formulas for outdoor wearables

Frequently Asked Questions (FAQ)

Yes, we provide rapid prototyping and low-volume sample runs for testing.

Absolutely. We can bond silicone with plastics or metals using advanced overmolding techniques.

Typical production takes 10–18 days after sample approval, depending on complexity.