Our Capabilities – Full-Service Custom Silicone Processing Factory in China

Precision Silicone Molding | OEM/ODM Solutions | Full Material Support

What We Do Best

WH Silicone is a custom silicone processing factory based in Dongguan, China, specializing in OEM silicone parts manufacturing using LSR, compression molding, and extrusion. As a full-service silicone factory, we provide end-to-end support for global brands, covering design review, material selection, tooling, prototyping, and mass production of silicone components. With over 10 years of experience in the silicone manufacturing industry, we offer reliable, scalable solutions for a wide range of applications — from medical-grade silicone parts to automotive silicone gaskets and wearable silicone accessories.

Core Silicone Processing Capabilities

LSR Silicone Molding (Liquid Silicone Rubber)

As an experienced LSR silicone manufacturer in China, we utilize fully automated injection machines for high-precision, flash-free silicone parts that meet FDA and ISO13485 standards.

Applications:

Medical-grade silicone components (syringe seals, valves)

Baby-safe products (nipples, pacifiers)

custom silicone Electronics wearables keypads wristbands

-

Medical-grade silicone components (syringe seals, valves)

-

Baby-safe products (nipples, pacifiers)

-

Electronics & wearables (keypads, wristbands)

Why Choose WH:

-

Cleanroom-ready production

-

Flash-free cold runner systems

-

Platinum-cured, biocompatible LSR

Compression Silicone Molding

-

Low-cost mold tooling

-

Excellent for wearable silicone, industrial dampers

-

Supports custom color matching and post-curing

Custom Silicone Extrusion

-

Capabilities:

-

Solid and sponge silicone extrusion

-

Custom dies for round, flat, U, P, or irregular profiles

-

Co-extrusion and multi-color striping

-

Custom Silicone Materials Expertise

We offer full material customization for your product’s specific needs — from food-safe silicone to self-lubricating elastomers.

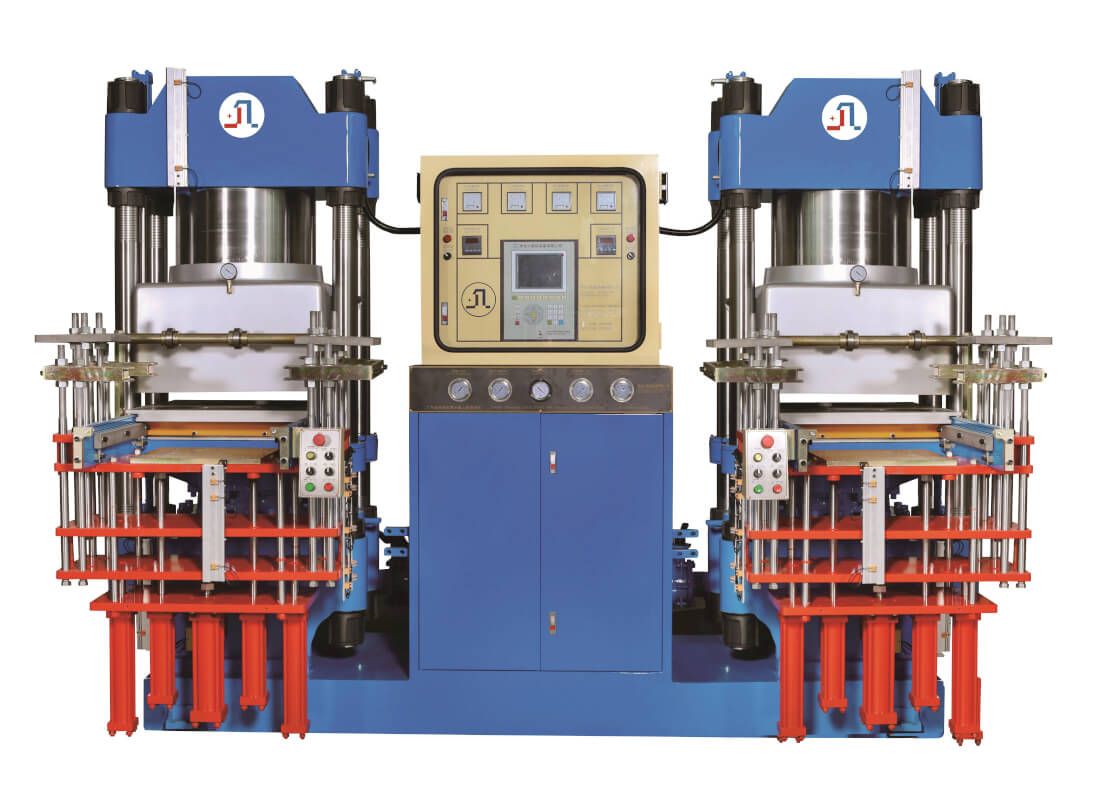

Well-Equipped Factory in Dongguan, China

Located in Dongguan City, Qishi Town, Huan Zhen Road No. 553-105, our silicone factory is fully equipped for ISO-certified silicone manufacturing.

Our equipment includes:

-

150T–300T LSR injection machines

-

100T–250T vacuum compression molding machines

-

Multi-line silicone extrusion systems

-

CNC mold fabrication center

-

Complete QC lab (tensile tester, durometer, aging chamber)

Rapid Prototyping & Small Batch Manufacturing

Looking for low-volume silicone production or rapid prototyping services? WH Silicone supports small batches for startups, engineers, and proofing runs.

Why choose WH silicone customization service

-

In-house aluminum tooling for quick turnaround

-

Sample mold delivery within 3–7 days

-

Full DFM and CAD support

-

Ideal for trial orders and crowdfunding projects

Engineering & Customization Services

From concept to mass production, our silicone engineering team helps with:

-

Tolerance analysis, CAD/STEP drawing review

-

Custom logo, branding, surface finish options

-

Overmolding with plastic/metal/electronic inserts

-

Silicone-to-metal/glass bonding techniques

-

Full OEM/ODM project execution

Scalable from Prototype to Mass Production

Whether you're an entrepreneur with a product idea or an established brand ready to scale, we support flexible MOQs, confidentiality via NDAs, and international logistics.

-

Why WH Silicone?

Why WH Silicone?

-

Experienced OEM silicone components supplier

-

Strong QA and IP protection

-

Short lead times and responsive service

-

Worldwide shipping and export support