Silicone Product Design for Mass Production | WH OEM Tips

Designing a silicone product is more than just the idea—it’s about making it manufacturable, scalable, and cost-effective. At WH Silicone, we work closely with OEM clients to turn concepts into optimized mass-producible products. Here’s what you need to consider.

🧩 Key Factors in Silicone Design for Manufacturing (DFM)

1. Wall Thickness & Uniformity

Avoid overly thin or inconsistent wall thickness. Ideal range for LSR: 0.6mm–3.0mm. This ensures even curing and reduces rejection rate.

2. Draft Angles

Apply 1°–3° draft angles to enable smooth demolding from compression or injection tools.

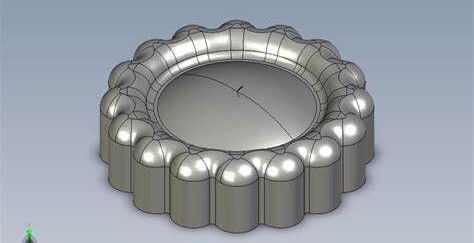

3. Undercuts & Complex Geometry

Minimize complex undercuts unless necessary—they increase tooling cost and cycle time.

4. Parting Line Placement

Design around a clean and flat parting line to avoid flash or post-processing.

⚙️ Mold Considerations: Design Affects Cost

-

Multi-cavity molds: Lower unit cost at high volume

-

Tool steel selection: Hardened steel lasts longer for mass runs

-

Ventilation: Critical for bubble-free silicone curing

💡 Tip: A simple design change can cut mold cost by 20–30%.

📦 Material Choice Impacts Production Flow

WH supports:

-

HTV silicone: Good for basic molded parts

-

LSR: Best for automated high-speed injection

-

Silicone foam: Ideal for lightweight cushioning components

We'll recommend the best based on target volume, cycle time, and function.

🔍 Case Study: Redesign Reduces Mold Cost by 32%

A wearable tech brand partnered with WH to produce a flexible silicone strap. After reviewing the original CAD:

-

Simplified grooves and thickness

-

Changed parting line

-

Used multi-cavity mold for 4x output

💡 Result: 32% tooling savings, 48% faster production cycle

🧠 Design Support at WH Silicone

Our team can support from:

-

2D/3D file review (STP, IGS)

-

Material and process recommendation

-

Rapid prototyping (within 5–7 days)

-

Mass production DFM adjustments

We work closely with your engineers or designers for best results.

💡 Summary

Optimizing your silicone design before tooling begins saves money, time, and trouble. Let WH Silicone help you go from sketch to scalable product—efficiently and affordably.